The Dutch construction sector faces the challenge of accelerating housing development while simultaneously improving sustainability and affordability. Industrialized construction is seen as an important part of the solution, primarily due to shorter construction times and lower building costs. However, a more industrial approach to building also results in CO₂ savings as a consequence of a different construction process.

CO₂ savings through more efficient logistics and reduced construction waste

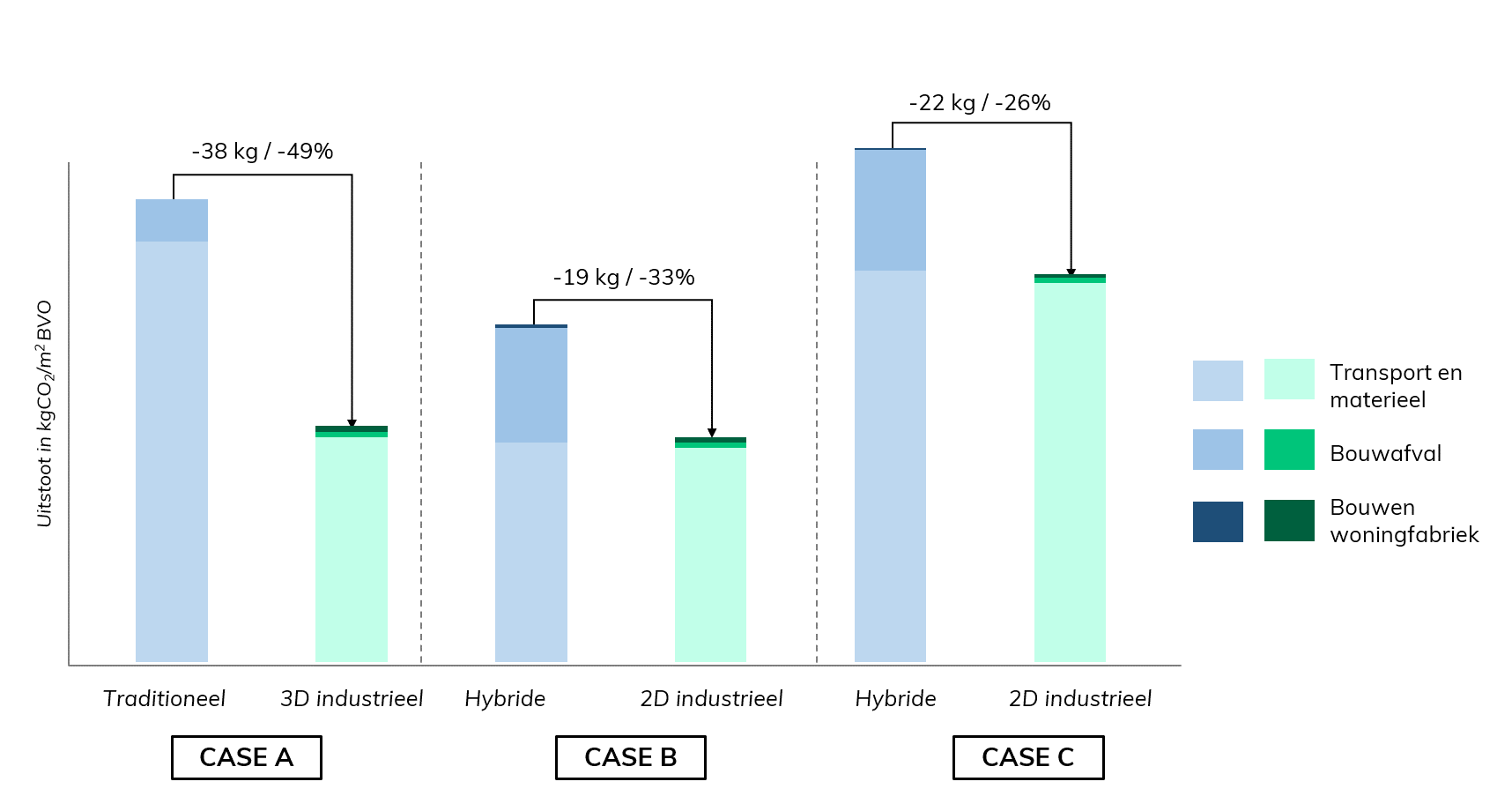

The CO₂ reduction of industrial construction stems from more efficient logistics, lower material usage, and shorter construction times. Among these, the more efficient deployment of logistics and equipment is the most significant factor. Initial indications based on three case studies show a reduction of 1 to 33 kg CO₂ per m² GFA compared to a traditionally executed construction project. The reduction in construction waste contributes an additional 6 to 21 kg CO₂ per m² GFA, partly because factory production processes are more efficient than on-site construction.

The construction of the housing factory itself results in negligible additional CO₂ emissions per factory-produced dwelling. Based on the three cases, this amounts to less than 1 kg CO₂ per m² GFA. This extra emission is minimal compared to the reductions achieved in transport, equipment use, and construction waste.

25–50% savings resulting from a different construction process

In total, an industrialized approach to building leads to an indicative CO₂ reduction of 19–38 kg CO₂ per m² GFA compared to traditional construction methods. In percentage terms, this corresponds to a 25–50% reduction in construction-process-related emissions.

To make the Environmental Performance of Buildings (MPG) methodology suitable for calculating the impact of different construction methods, adjustments to the calculation method are needed. We recommend distinguishing between the Product Stage (A1–A3: construction materials) and the Construction Stage (A4–A5: construction method). Implementing this adjustment will require efforts from multiple parties, including the national government, the National Environmental Database (NMD), project developers, and concept developers. Once the environmental impact can be estimated more accurately, it will also be possible to take more targeted steps to reduce it.

*Please note that this publication is only available in Dutch.